Valves play an integral role in the piping system and this is why you can’t ignore them when talking about the system. No matter whether it is liquid, vapour or oil, the valves control the flow of content and pressure as well.

Here are the top 3 types of valves used in different industries that you need to know about.

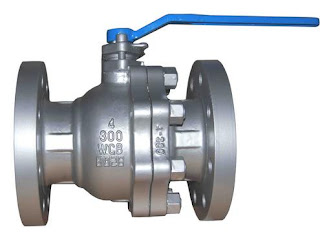

1. Ball valves

A ball valve comes with a ball shaped disk and its main function is to control the flow through it. Since the hole in this valve is in line with the body inlet, the open in ball valve ensures easy passing of the content.

These valves can operate in extreme temperature as they are made of materials like Teflon. They can operate in as high as 500 degree C and as low as 200 degree C.

2. ARV or ARC valves

These valves are called 'Automatic Recirculation Valve' and 'Automatic Recirculation Control' valves and are multifunctional. These valves also help in valve automation process though the main function is to ensure a minimum flow through centrifugal pump.

Gaskets like the ring joint gasket are also essential in the piping system as they are used in sealing pipes.

3. Gate valves

In situations when there is the need of straight line flow with minimum restriction, these valves are important. The gate valve is designed to stop or start a flow and is kept either fully closed or open.

We hope this post must have given you an idea about a few top valves that play an integral role in industries today.

Here are the top 3 types of valves used in different industries that you need to know about.

1. Ball valves

A ball valve comes with a ball shaped disk and its main function is to control the flow through it. Since the hole in this valve is in line with the body inlet, the open in ball valve ensures easy passing of the content.

These valves can operate in extreme temperature as they are made of materials like Teflon. They can operate in as high as 500 degree C and as low as 200 degree C.

2. ARV or ARC valves

These valves are called 'Automatic Recirculation Valve' and 'Automatic Recirculation Control' valves and are multifunctional. These valves also help in valve automation process though the main function is to ensure a minimum flow through centrifugal pump.

Gaskets like the ring joint gasket are also essential in the piping system as they are used in sealing pipes.

3. Gate valves

In situations when there is the need of straight line flow with minimum restriction, these valves are important. The gate valve is designed to stop or start a flow and is kept either fully closed or open.

We hope this post must have given you an idea about a few top valves that play an integral role in industries today.